Hall 7

Wittur at Interlift 09

Wittur has been present at Interlift 09, the international trade fair for elevators, components and accessories that took place at Augsburg Exhibition Center from October 13th to October 16th, 2009.

At Wittur booth in Hall 7, stand 721, visitors coming from all over the world have been able to experience Wittur extensive range of products directly and got a glimpse of new products to come.

At Wittur booth in Hall 7, stand 721, visitors coming from all over the world have been able to experience Wittur extensive range of products directly and got a glimpse of new products to come.

Mr. Sergio Biglino, Executive Vice President Corporate Sales & Marketing, Wittur Group, comments in a favourable way the outcome of the exhibition: "Wittur was pleased to meet its customers at Interlift 09 with innovations for energy efficiency, modernizations and accessibility, safety and special expertise in tailored lift projects.

As a global supplier, Wittur is transferring its worldwide competence to a new generation of lift components: smaller, less power-hungry, more flexible, easier to install. Many of this products were on display in Wittur stand in Hall 7”.

Wittur has been the first company to obtain the A-class energy efficiency certificate for complete MRL W-Line lifts made mainly using Wittur components at Wittur headquarters in Wiedenzhausen, Germany, as well as in Wittur production companies in Istanbul, Turkey and Scheibbs, Austria.

Most of the components used on these lifts were present on the Wittur stand, namely:

- The new “ECO” series of gearless drives designed and produced by Wittur Electric Drives GmbH in Dresden, Germany. They feature a reduced current consumption of as much as 20% depending from the application;

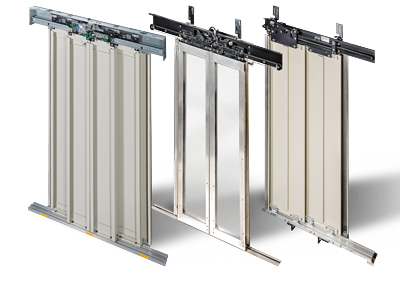

- Hydra Plus car doors, the internationally acclaimed door series which stands for utmost reliability, presented with the new generation of ECO+ and MIDI+ door drives. This new drives substantially reduce the energy consumption required for each opening/closing cycle (up to 48% compared to previous design) and have a very low standby consumption;

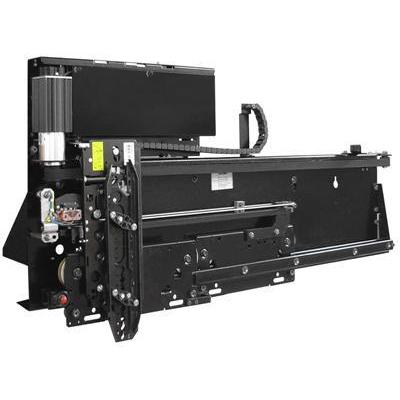

- The new Hydraulic pump unit HI produced by Wittur Hydraulic Drives S.r.l. in Bergamo, Italy, equipped with inverter. The WITTUR HI pump unit is the only unit currently on the market that is able to control the car movement through an inverter only, thereby optimizing the motor efficiency at any given moment of the lift operation. Thanks to its specific configuration, the WITTUR HI pump unit is already compliant with the new EN 81-2 pr.A3 Standards, which will come into force in 2010.

- The Hydraulic pump unit HE with electronic valve produced by Wittur Hydraulic Drives S.r.l. in Bergamo, Italy, which offers significant energy savings (up to 30% compared with traditional pump units installed in lifts with a short travel height)

Another section of the booth has been dedicated to Wittur experience in safety components:

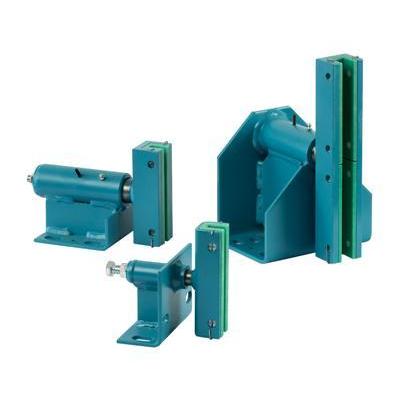

- UCM solution for protection against unintended car movement. The solution consists of electronic overspeed governor EOS and bi-directional progressive safety gear BSG-25P. Wittur EOS electronic overspeed governor, the innovative solution to comply with the new uncontrolled car movements directive. Thanks to the continuous electronic monitoring of position, speed and acceleration EOS offers a higher accuracy of measurement compared to conventional governors.

Modernization and accessibility solutions were also featured on Wittur Booth:

- Fineline extended range of automatic lift doors: an extremely compact footprint designed to insert an automatic car door and an automatic landing door in a minimal depth (115 mm) when modernizing an existing lift with swing doors.

- Hydra Plus 3000 car doors, presented in a new version with reduced sill thickness starting from 50 mm and equipped with the new generation of ECO+ and MIDI+ door drives. New solutions such as the possibility to place the motor on upper left or right without adapters account for high installation versatility

- AMD car door operator modernization package. A perfect solution for car door operator modernization, with a wide rangeof pre-designed and customised solutions available

- ECO Bus, the new patented folding car door available with flat or W-panels. ECO Bus features a light but strong design with sturdy deformation-resistant panels coupled together using high-strength extruded aluminium hinges

A special section was set up to show Wittur expertise in dealing with special applications, where customer targets are set very high:

- Wittur round glass OSAKA lift car with LUNA round glass doors

- Wittur Marine doors. A complete range of lift doors for passenger ships, cruise ships, cargo ships and off-shore platforms, designed and tested to work in extreme environments according to LD 96/98/EC, Marine Equipment (MED) and International Marine Organization (IMO) standards

- HYDRA and PEGASUS full range of landing and car door types now available with vandal resistant certification according to EN 81-71:2005 (class 1)

- Wittur MRL H-Pack system: a package of major lift components designed and engineered for an optimal interface. A dedicated solution for applications in hospital lifts according to ISO 4190 Class III.

- Wittur Miami passenger car: WITTUR car equipped with lean light panels directly produced from Super Mirror stainless steel and LED lighting, available in a wide range of dimensions according to ISO 4190.

- Wittur HHL W line lifting platform, suitable for removing architectural barriers in residential, office or public buildings. This is a Plug-and-play system for fast and easy installation, available with a wide range of finishing materials to complement any interior design and compliant with the requirements of the new Machine Directive 2006/42/EC and the prEN 81-41

Wittur was also present at the VFA-Forums in Hall 2 during the exhibition with four presentations:

"Energy and Ecology Focus of the Wittur Group", Markus Hößle, Thursday 15.10.09, 09:30 - 09:50

"Trends for Modern Gearless Traction Machines", Jens Werdin, Tuesday 13.10.09, 14:00 - 14:20

"Rules and Regulations and Their Influence on a Lift according to the New Machine Directives", Thomas Bichler, Wednesday 14.10.09, 15:30 - 15:50

"UCM-Technology", Florian Leutner, Friday 16.10.09, 13:00 - 13:20

More and more about Interlift 09: www.interlift.de

READ MORE

Wittur at 2009 Moscow Lift Exhibition

Great interest for Wittur stand at “Lift EXPO Russia 2009” exhibition, that was held from May 27th to 29th, 2009 at All Russian Exhibition Center in Moscow, Russia.

In this international context Wittur Group has displayed the latest innovations from its production range: Hydra range of doors according to the various worldwide certifications, gearless drives manufactured by Wittur Electric Drives.

Moreover, a wide range of Safety devices and lift cabins featuring new LED lighting to reduce overall power consumption were also present on the stand, where they attracted the attention of the many visitors.

In this international context Wittur Group has displayed the latest innovations from its production range: Hydra range of doors according to the various worldwide certifications, gearless drives manufactured by Wittur Electric Drives.

Moreover, a wide range of Safety devices and lift cabins featuring new LED lighting to reduce overall power consumption were also present on the stand, where they attracted the attention of the many visitors.

READ MORE

Wittur Management Meeting, June 30 - July 2nd 2009

Setting The Sails

A group of Managers coming from all Wittur Production and Trading companies have gathered together in Prien am Chiemsee in Southern Germany for the Wittur Management Meeting 2009.

This traditional yearly meeting serves the purpose to analyse the lift market, discuss Wittur Group performances and agree on the future strategies regarding sales action, new products, possible new markets.

The 2009 theme has been, “Setting the Sails” – keeping a stable course in a difficult economic environment. Which means straightening the sales, improving tools and processes and increasing customers’ needs – step by step on our “Road to Excellence”.

An outstanding topic for 2009 meeting was also Wittur Corporate Values: the formal definition of the values underlining the everyday work of each Wittur employee.

This traditional yearly meeting serves the purpose to analyse the lift market, discuss Wittur Group performances and agree on the future strategies regarding sales action, new products, possible new markets.

The 2009 theme has been, “Setting the Sails” – keeping a stable course in a difficult economic environment. Which means straightening the sales, improving tools and processes and increasing customers’ needs – step by step on our “Road to Excellence”.

An outstanding topic for 2009 meeting was also Wittur Corporate Values: the formal definition of the values underlining the everyday work of each Wittur employee.

READ MORE

Official Opening Ceremony

Wittur s.r.o. new production facility in Slovakia

The official opening of our new plant in Krupina, Slovakia, took place on 29 May 2009.

Over a production area of approx. 5,000 square metres, Wittur s.r.o. is now manufacturing frames for cabins and counterweights, safety devices, door drives and door operating mechanisms. Tens of thousands of these products will be leaving the Wittur s.r.o. works each year – offering our traditional quality and on-time delivery.

Thanks to the close co-operation between Krupina and Wittur GmbH technicians in Scheibbs, Austria , the layout of these facilities has been designed from the start according to the standards of the Wittur Production System (WPS).

After one year of planning, followed by a six-month construction period, the light-flooded production facilities and architecturally attractive office building have been released for production start-up.

READ MORE

Istanbul, Turkey

Wittur at Asansör 2009

Wittur has experienced an overcrowded stand at Asansör 2009 exhibition, that was held from 9 to 12 April 2009 at Tuyap Exhibition Center in Istanbul, Turkey.

The visitors on the stand have had the opportunity to experience the latest innovations from Wittur production range, such as Hydra range of doors according to the various worldwide certifications, the bed lift for hospitals H-Pack and lift cabins featuring LED lighting to reduce overall power consumption.

Attention to energy efficiency was also evident from the “Regen Operation” system: a Lift is used to produce energy during operation by exploiting its gearless drive. Furthermore, an hydraulic cylinder in “slim” version was shown and appreciated for the reduced quantity of oil needed.

A wide range of safety systems was also on the stand, including EOS, the new generation of electronic overspeed governors that, thanks to its acceleration based tripping system guarantees reduced intervention times and guarantees a higher safety level.

The visitors on the stand have had the opportunity to experience the latest innovations from Wittur production range, such as Hydra range of doors according to the various worldwide certifications, the bed lift for hospitals H-Pack and lift cabins featuring LED lighting to reduce overall power consumption.

Attention to energy efficiency was also evident from the “Regen Operation” system: a Lift is used to produce energy during operation by exploiting its gearless drive. Furthermore, an hydraulic cylinder in “slim” version was shown and appreciated for the reduced quantity of oil needed.

A wide range of safety systems was also on the stand, including EOS, the new generation of electronic overspeed governors that, thanks to its acceleration based tripping system guarantees reduced intervention times and guarantees a higher safety level.

READ MORE

WITTUR Sweden AB invites you to 2009's annual meeting for lift people

Exhibition '09

June 2nd-3rd, 2009

It's time again for Wittur to display the latest products from our wide range of supply!

Some products that we will be showing:

- NEW Pegasus program

- EOS Electronic OSG

- Lift Machines geared & gearless

- Lift Controllers

- Light Screens

- with according technical support

For further information: info@wittur.se or +46 856475540

READ MORE

WITTUR at WEEE ‘08, Langfang, China

WITTUR at WEEE 08

WITTUR attended the most important elevator industry exhibition in China - WEEE ‘08 (World Elevator & Escalator Expo ‘08) on April 22-25 in Lang Fang.

WITTUR’s complete range of products and services were clearly displayed to customers and interested visitors in a 207 m² area. Samples of all WITTUR components were exhibited in the booth, such as Hydra-Plus and Augusta doors, ESV Framed Glass Doors, Panoramic Car, gearless drives and safety devices.

WITTUR also took the opportunity to debut its new Web platform www.wittur.com, which has been translated for the occasion into Chinese.

We would like to express its grateful thanks to all visitors!

You are always welcome to contact us for more information and requests.

WITTUR’s complete range of products and services were clearly displayed to customers and interested visitors in a 207 m² area. Samples of all WITTUR components were exhibited in the booth, such as Hydra-Plus and Augusta doors, ESV Framed Glass Doors, Panoramic Car, gearless drives and safety devices.

WITTUR also took the opportunity to debut its new Web platform www.wittur.com, which has been translated for the occasion into Chinese.

We would like to express its grateful thanks to all visitors!

You are always welcome to contact us for more information and requests.

READ MORE

WITTUR at ELEVCON 08, Thessaloniki, Greece

ELEVCON

WITTUR will be present at ELEVCON 2008, Thessaloniki, Greece (11-13 June 2008), the 17th International Congress on Vertical Transportation Technologies.

Mr. Klaus Schaufler and Mr. Markus Erndl from WITTUR will make a speech on the “Use of Electronic Systems for Safety Components in Elevators” and “Access to Elevators According Actual Code and Market Demands”.

If you would like to have more information about the programme of these 3 days Congress, you can visit the website: http://www.elevcon.com/

Mr. Klaus Schaufler and Mr. Markus Erndl from WITTUR will make a speech on the “Use of Electronic Systems for Safety Components in Elevators” and “Access to Elevators According Actual Code and Market Demands”.

If you would like to have more information about the programme of these 3 days Congress, you can visit the website: http://www.elevcon.com/

READ MORE

From October 20th to October 22nd, 2010

Wittur at EURO-LIFT, Poland

Wittur was present at EURO-LIFT 2010, the international trade fair for elevators, components and accessories that took place in Kielce, Poland, from October 20th to October 22nd, 2010.

The visitors were able to experience the extensive range of Wittur products and the latest innovations, including the MDS1 modular door system, UCM device against uncontrolled car movement and Wittur servogearless permanent magnet gearless drives S1.

A Commission headed by Prof. Jerzy Kwaśniewski selected the most interesting technical innovations presented in the exhibition. Wittur EOS electronic overspeed governor was awarded as one of the best technical innovations of the exhibition during the official EURO-LIFT dinner on October 21st.

Mr. Markus Hoessle from Wittur Holding and Mr. Karl Sturmleicher from Wittur GmbH were featured in the Technical forum agenda respectively with a presentation about “Energy efficient lift components” and “New Safety Components against Unintended Car Movements at Landings with Open Doors”.

The visitors were able to experience the extensive range of Wittur products and the latest innovations, including the MDS1 modular door system, UCM device against uncontrolled car movement and Wittur servogearless permanent magnet gearless drives S1.

A Commission headed by Prof. Jerzy Kwaśniewski selected the most interesting technical innovations presented in the exhibition. Wittur EOS electronic overspeed governor was awarded as one of the best technical innovations of the exhibition during the official EURO-LIFT dinner on October 21st.

Mr. Markus Hoessle from Wittur Holding and Mr. Karl Sturmleicher from Wittur GmbH were featured in the Technical forum agenda respectively with a presentation about “Energy efficient lift components” and “New Safety Components against Unintended Car Movements at Landings with Open Doors”.

READ MORE

WITTUR at EXPO ELEVADOR 2008, Sao Paulo, Brazil

EXPO ELEVADOR 2008

WITTUR attended the biggest Latin American Elevator Industries exhibition in Brasil - EXPO ELEVADOR 2008 - on August 20-21 in Sao Paulo.

WITTUR’s complete range of products and services were clearly displayed to customers and interested visitors. Samples of all WITTUR components were exhibited in its booth (#1), such as the new folding door ECOBUS, glass HYDRAPLUS doors, hydraulic drives and gearless drives S1/S2.

We would like to express our grateful thanks to all visitors!

You are always welcome to contact us for more information and requests.

READ MORE

Since 1977 Wittur supplies the lift industry with versatile and high-quality doors.

Since 1977 Wittur supplies the lift industry with versatile and high-quality doors. Since 1977 Wittur has been providing the lift industry with versatile and high-quality doors. More than 30 years later Wittur is the leading company in the lift doors segment, with state-of-the-art technical solutions and unparalleled product range. Regardless of whatever your lift requires - a round door with panoramic panels rather than a straight or a folding one - Wittur can supply the best solution for your needs.

Since 1977 Wittur has been providing the lift industry with versatile and high-quality doors. More than 30 years later Wittur is the leading company in the lift doors segment, with state-of-the-art technical solutions and unparalleled product range. Regardless of whatever your lift requires - a round door with panoramic panels rather than a straight or a folding one - Wittur can supply the best solution for your needs. Research for innovative solutions and rigid control of product quality are key features of Wittur Safeties.

Research for innovative solutions and rigid control of product quality are key features of Wittur Safeties.  Wittur offers a wide range of car and counterweight frames. Modularly conceived, these components are very flexible in terms of rated load, height and width. The wide range of accessories includes safety gears, suspension pulleys, compensation chain and travelling cable hangers, allowing configurations suitable for different shaft layouts, lift designs and rated speeds. Wittur can also supply special frames for tailored projects.

Wittur offers a wide range of car and counterweight frames. Modularly conceived, these components are very flexible in terms of rated load, height and width. The wide range of accessories includes safety gears, suspension pulleys, compensation chain and travelling cable hangers, allowing configurations suitable for different shaft layouts, lift designs and rated speeds. Wittur can also supply special frames for tailored projects.

Research for innovative solutions and rigid product quality control are key features of Wittur Safeties.

Research for innovative solutions and rigid product quality control are key features of Wittur Safeties. According to EN81-1/2 A3 and EN81-21 A1 (new lifts in existing buildings), new lifts installed after January 1st 2012 must be equipped with a system to prevent a car moving away from the floor with the landing door not in the locked position and the car door not in the closed position.

According to EN81-1/2 A3 and EN81-21 A1 (new lifts in existing buildings), new lifts installed after January 1st 2012 must be equipped with a system to prevent a car moving away from the floor with the landing door not in the locked position and the car door not in the closed position.

Since 1977 Wittur supplies the lift industry with versatile and high-quality doors.

Since 1977 Wittur supplies the lift industry with versatile and high-quality doors..jpg) Since 1977 Wittur supplies the lift industry with versatile and high-quality doors.

Since 1977 Wittur supplies the lift industry with versatile and high-quality doors. Since 1977 Wittur supplies the lift industry with versatile and high-quality doors.

Since 1977 Wittur supplies the lift industry with versatile and high-quality doors.