WITTUR’S SOLUTION FOR MODERNISATION

The MRM W-Line, Wittur’s flexible machine roomless electric lift, offers an ideal solution for new lifts in existing buildings based on an innovative modular design. The MRM W-Line has been designed specifically to permit optimised use of space and energy consumption in buildings with up to 10 stops and a travel height of up to 30m, with a maximum rated load of 1000 kg and a maximum rated speed of 1 m/s

NORM COMPLIANT

The MRM W Line fulfills all the requirements of the Lift Directive 95/16/EC, as well as the standards EN81-1:A3, EN81-28 (remote alarm on passenger and goods lifts) and EN81-58 (landing door fire resistance test). Wittur additionally offers the option of supplying the MRM W Line to comply with EN81-70 (designed to improve accessibility), EN81-73 (behaviour of lifts in the event of fire) and EN81-21 (reduced pit and head room).

Upon request, the MRM W Line can be manufactured to comply with the standards EN81-72 (firefighters lifts, subject to technical feasibility analysis) and EN81-71 (vandal-resistant).

Upon request, the MRM W Line can be manufactured to comply with the standards EN81-72 (firefighters lifts, subject to technical feasibility analysis) and EN81-71 (vandal-resistant).

QUICK INSTALLATION

The MRM W-Line is easy and quick to install. A new modular logistics concept has been designed so that each box is opened only as and when its contents are needed, thereby avoiding time wastage and confusion. Furthermore, each component has its own user-friendly manual, making the steps of the assembly process easy to follow and fail-safe. The assembly of the electrical components has also been made simpler thanks to Wittur’s “Plug and Play” concept. All the customer has to do is connect the components as instructed in the manuals.

LOW MAINTENANCE

The MRM W-Line requires minimal maintenance due to the high quality and simplicity of its design. Besides avoiding unnecessary costs, this adds to the safety of the assembly and maintenance personnel.

Wittur Inside: the MRM W-Line incorporates components manufactured by Wittur to the highest standards of quality, reliability and safety.

REDUCED ENERGY CONSUMPTION

The MRM W-Line offers low energy consumption thanks to its efficient ECO design. Both the gearless drive motor and car door motor incorporate cuttingedge technology in the form of permanent magnets which guarantee reduced energy consumption during the running of the lift, and whose “Sleep Mode” (upon request) reduces energy consumption to “0” watts when the lift is not being used.

COMPACT AND FLEXIBLE DESIGN

The MRM W Line makes optimal use of available space and can be installed in any type of shaft with a pit depth starting at just 320 mm (only for 320 kg version) and headroom starting at just 2800 mm (both according to EN81-21). The MRM W Line uses Wittur bedplates and WSG T-Series gearless drive which offers smaller dimensions through the use of smaller traction sheaves with reduced rope sections. The compact design does not compromise a wide range of door installation: all Hydra, MDS1, Fineline, Ecobus, and Swings series are available with 1 or 2 entrances (2-90º / 2-180º) option. Furthermore, the controller can be perfectly integrated into the design of the elevator, fitting snuggly into a compact controller cabinet placed neatly in front of the frame of the landing door itself (technical study requested in case of reduced headroom). MRM W Line 320 dimensions are suitable to be fitted into existing hydraulic lift shafts for modernisation purposes.

A SILENT AND COMFORTABLE RIDE

Through the combination of highly efficient mechanical and electrical components (like the gearless drive), the isolation of vibrating elements, drive control by means of a frequency inverter, balanced rope arrangement and low friction sliding guide shoes, it has been possible to obtain a high ride comfort and low noise levels compliant with VDI 2566-2. The optional “Comfort Kit”, silent blocks made of platted stainless steel wiring, offers a reduction of up to 15% in the level of vibration of the drive, obtaining an enhanced ride comfort and preventing any vibrations from travelling through the building. The noise level perceived by the passenger from inside the car is limited to 50 dBA.

OPTIMISED PACKAGING

A new and user-friendly logistics concept has been designed for Wittur’s new range of elevator systems. The elevator’s sub-components are delivered in pre-established spacesaving and highly recyclable modules which have been clearly identified and numbered according to the order in which they are needed within the elevator’s assembly sequence. This greatly optimises handling and increases safety during transportation. Each module is easily identifiable and is opened only when its contents are needed, thereby increasing the ease of assembly whilst dramatically reducing the risk of loss of components from boxes that have been opened before it was necessary. Once the contents of the box have been used, the box can be removed from the site and recycled.

AVAILABLE FINISHES

Despite its simplicity, the MRM W-Line offers a wide and versatile range of options and car decorations. The standard decorations, with their functional designs, offer the added advantage of a short production lead-time, but the MRM W-Line can be supplied in a most versatile range of decorations to suit any request including skinplate, melamine, laminate, wood, stainless steel and glass.

For the full range of available decorations, please contact us.

Technical features

The MRM W-Line offers versatile solutions with single and double entrances at 90º and 180º with various automatic door solutions.

|

Entrances

|

Rated Load Q (kg) |

Roping | Rated Speed V (m/s) |

Internal car dimensions

b1 x d1 (mm) |

Clear

Opening b2 (mm) |

Min. Shaft width

b3 PR (mm) |

Min. Shaft width b3 PR+HR (mm) |

Min. shaft depth

d2 (mm) |

Min. pit depth EN81-1

d3

(mm) |

Headroom

h1 (mm) |

Min. pit depth EN81-21 d3 (mm) |

Headroom EN81-21 h1 (mm) |

|

1 - 0°

|

320

|

1:1 | 1,00 |

900x1000

|

700

|

b1 + 350

|

b1 + 430 |

d1 + 250

|

1100 |

3400

|

350(1) | 2600(2) |

|

2 - 180°

|

320

|

1:1 | 1,00 |

770x1120

|

700

|

b1 + 460

|

b1 + 460 |

d1 + 340

|

1100 |

3400

|

350(1) | 2600(2) |

|

2 - 90°

|

320

|

1:1 | 1,00 |

820x1050

|

700

|

b1 + 460

|

b1 + 540 |

d1 + 275

|

1100 |

3400

|

350(1) | 2600(2) |

| 1 - 0° | 450 | 2:1 | 1,00 | 1000x1200 | 800 | b1 + 420 | b1 + 420 | d1 + 250 | 1100(1) | 3400 | 380(1) | 2600(2) |

| 2 - 180° | 450 | 2:1 | 1,00 | 1000x1200 | 800 | b1 + 420 | b1+420 | d1 + 340 | 1100(1) | 3400 | 380(1) | 2600(2) |

| 2 - 90° | 450 | 2:1 | 1,00 | 1000x1200 | 800 | b1 + 550 | b1+550 | d1 + 250 | 1100(1) | 3400 | 380(1) | 2600(2) |

| 1 - 0° | 630 | 2:1 | 1,00 | 1100x1400 | 900 | b1 + 420 | b1 + 420 | d1 + 250 | 1100(1) | 3400 | 380(1) | 2600(2) |

| 2 - 180° | 630 | 2:1 | 1,00 | 1100x1400 | 900 | b1 + 420 | b1 + 420 | d1 + 340 | 1100(1) | 3400 | 380(1) | 2600(2) |

| 2 - 90° | 630 | 2:1 | 1,00 | 1200x1200 | 900 | b1 + 550 | b1 + 550 | d1 + 250 | 1100(1) | 3400 | 380(1) | 2600(2) |

| 1 - 0° | 1050 | 2:1 | 1,00 | 1100x2100 1400x1600 |

900 | b1 + 500 | b1 + 500 | d1 + 250 | 1100(1) | 3500 | 450(1) | 2800(3) |

| 2 - 180° | 1050 | 2:1 | 1,00 | 1100x2100 1400x1600 |

900 | b1 + 500 | b1 + 500 | d1 + 340 | 1100(1) | 3500 | 450(1) | 2800(3) |

| 2 - 90° | 1050 | 2:1 | 1,00 | 1400x1600 | 900 | b1 + 600 | b1 + 600 | d1 + 250 | 1100(1) | 3500 | 450(1) | 2800(3) |

HR: Reduced headroom

MDS1 doors

(1): Rubber floor (check the planning manual for 2-90°)

(2): Car height 2000 mm (2170 mm, h1 ≥ 2800 mm)

(3): Car height 2000 mm (2170 mm, h1 ≥ 3000 mm)

NOTE: The dimensions of the car are available upon request in steps of 50mm.

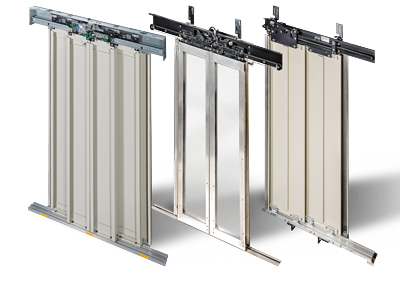

自1977年来,威特就开始为电梯行业提供多功能、高品质的轿厢门。设计灵活,加上通过了一系列认证,使威特层门能够适应各种应用。有多种表面装饰和规格,因此能适合各种环境:从住宅到高档写字楼、从外部设施到豪华的水上项目、从工业建筑到医院。

自1977年来,威特就开始为电梯行业提供多功能、高品质的轿厢门。设计灵活,加上通过了一系列认证,使威特层门能够适应各种应用。有多种表面装饰和规格,因此能适合各种环境:从住宅到高档写字楼、从外部设施到豪华的水上项目、从工业建筑到医院。 Since 1977 Wittur has been providing the lift industry with versatile and high-quality doors. More than 30 years later Wittur is the leading company in the lift doors segment, with state-of-the-art technical solutions and unparalleled product range. Regardless of whatever your lift requires - a round door with panoramic panels rather than a straight or a folding one - Wittur can supply the best solution for your needs.

Since 1977 Wittur has been providing the lift industry with versatile and high-quality doors. More than 30 years later Wittur is the leading company in the lift doors segment, with state-of-the-art technical solutions and unparalleled product range. Regardless of whatever your lift requires - a round door with panoramic panels rather than a straight or a folding one - Wittur can supply the best solution for your needs.

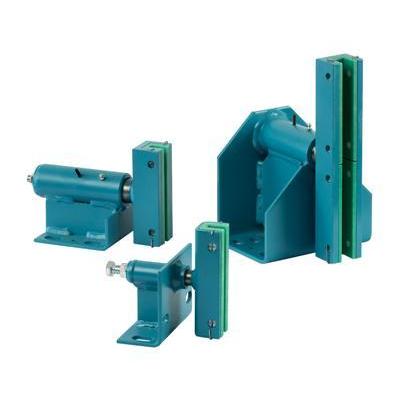

Wittur offers a wide range of car and counterweight frames. Modularly conceived, these components are very flexible in terms of rated load, height and width. The wide range of accessories includes safety gears, suspension pulleys, compensation chain and travelling cable hangers, allowing configurations suitable for different shaft layouts, lift designs and rated speeds. Wittur can also supply special frames for tailored projects.

Wittur offers a wide range of car and counterweight frames. Modularly conceived, these components are very flexible in terms of rated load, height and width. The wide range of accessories includes safety gears, suspension pulleys, compensation chain and travelling cable hangers, allowing configurations suitable for different shaft layouts, lift designs and rated speeds. Wittur can also supply special frames for tailored projects.

创新的解决方案研究和严格的产品质量控制是威特安全部件的主要特色。产品系列包括不定向/双向同步和渐进式安全钳。也可提供上升轿厢超速保护装置。

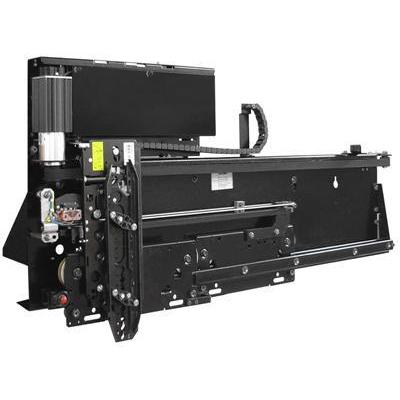

创新的解决方案研究和严格的产品质量控制是威特安全部件的主要特色。产品系列包括不定向/双向同步和渐进式安全钳。也可提供上升轿厢超速保护装置。 According to EN81-1/2 A3 and EN81-21 A1 (new lifts in existing buildings), new lifts installed after January 1st 2012 must be equipped with a system to prevent a car moving away from the floor with the landing door not in the locked position and the car door not in the closed position.

According to EN81-1/2 A3 and EN81-21 A1 (new lifts in existing buildings), new lifts installed after January 1st 2012 must be equipped with a system to prevent a car moving away from the floor with the landing door not in the locked position and the car door not in the closed position. 所有井道附件对于保证电梯的正常运行和使用寿命都是至关重要的。这正是威特提供以下各种附件的原因:

所有井道附件对于保证电梯的正常运行和使用寿命都是至关重要的。这正是威特提供以下各种附件的原因:

Since 1977 Wittur supplies the lift industry with versatile and high-quality doors.

Since 1977 Wittur supplies the lift industry with versatile and high-quality doors..jpg) Since 1977 Wittur supplies the lift industry with versatile and high-quality doors.

Since 1977 Wittur supplies the lift industry with versatile and high-quality doors. Since 1977 Wittur supplies the lift industry with versatile and high-quality doors.

Since 1977 Wittur supplies the lift industry with versatile and high-quality doors.